Global Solutions

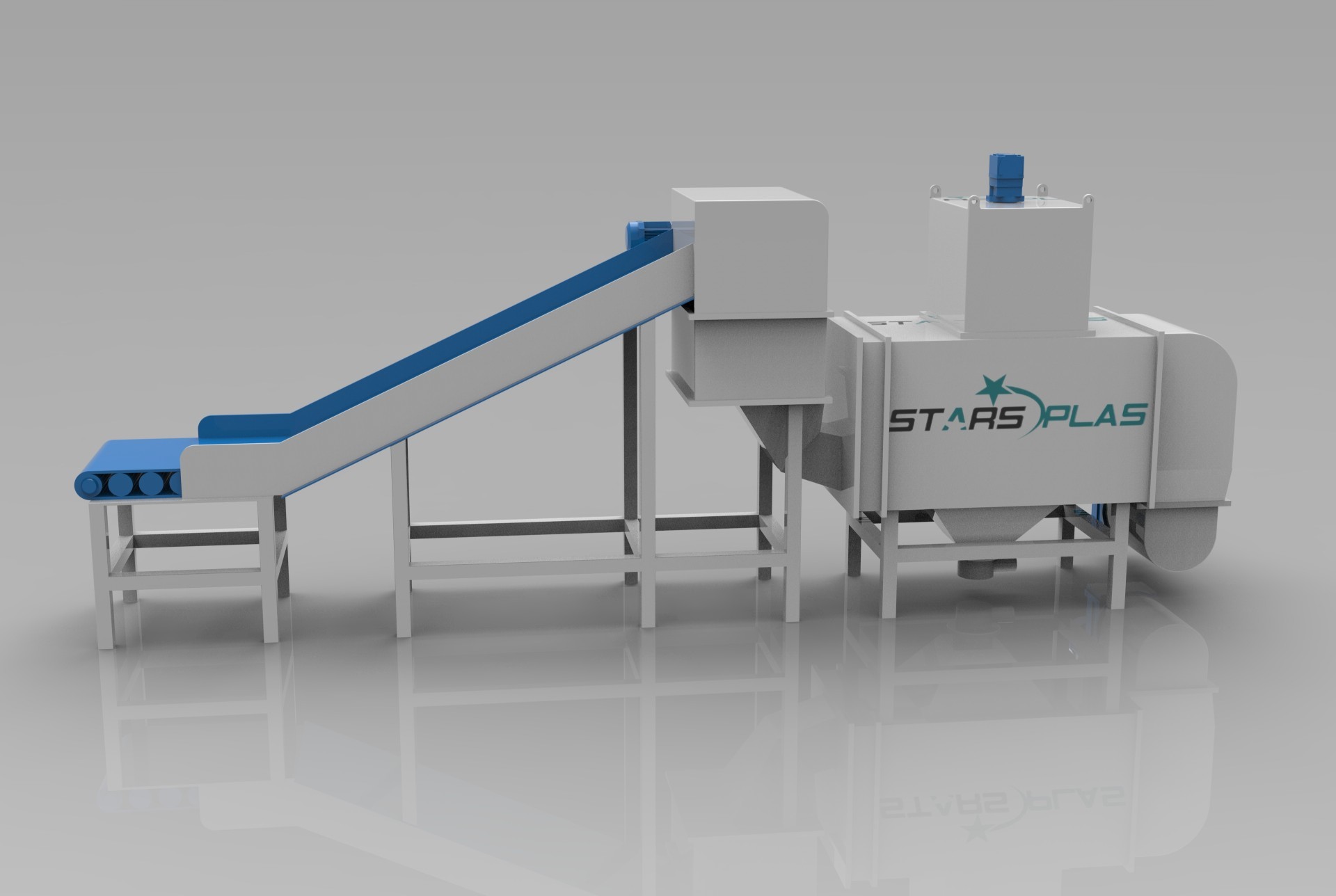

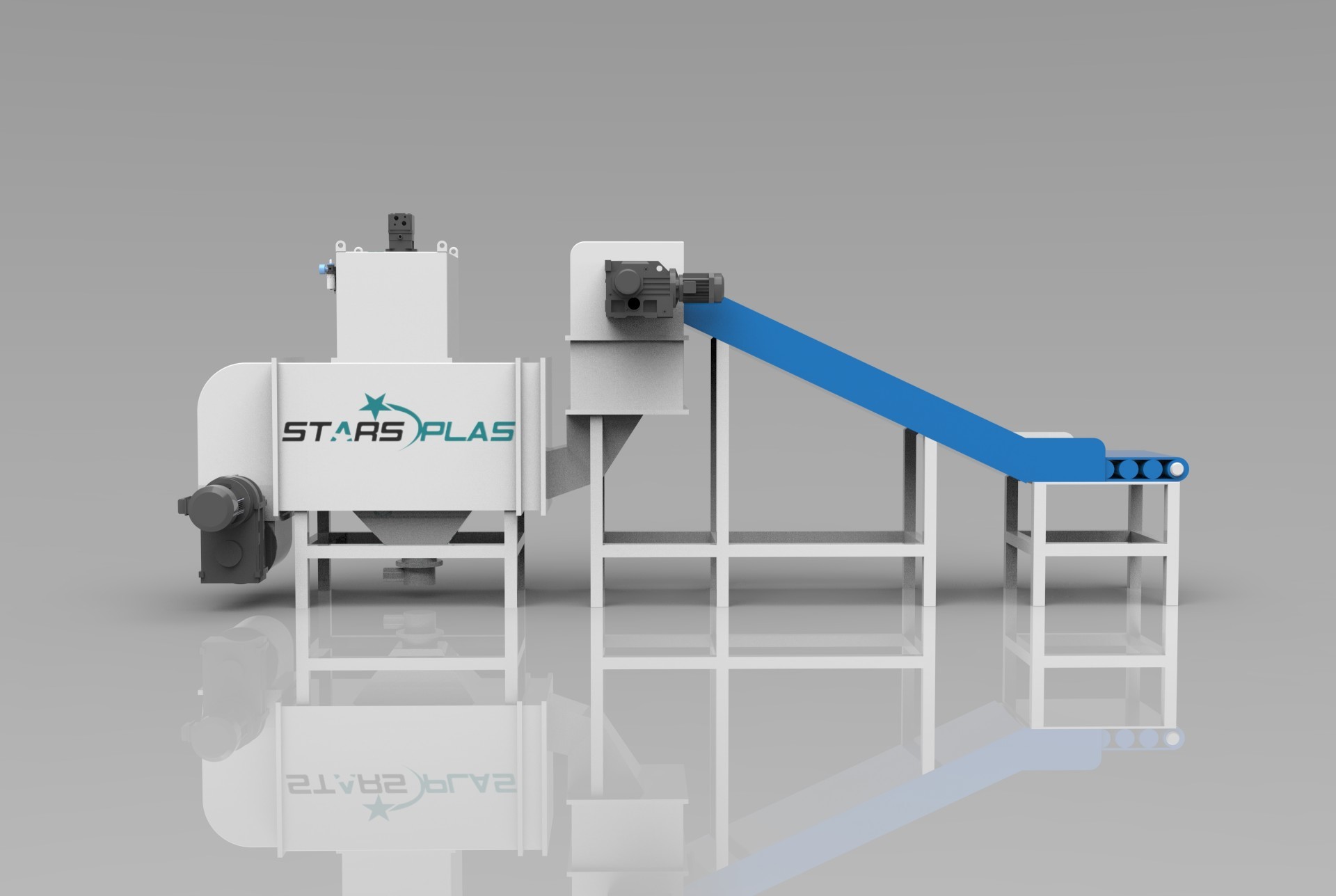

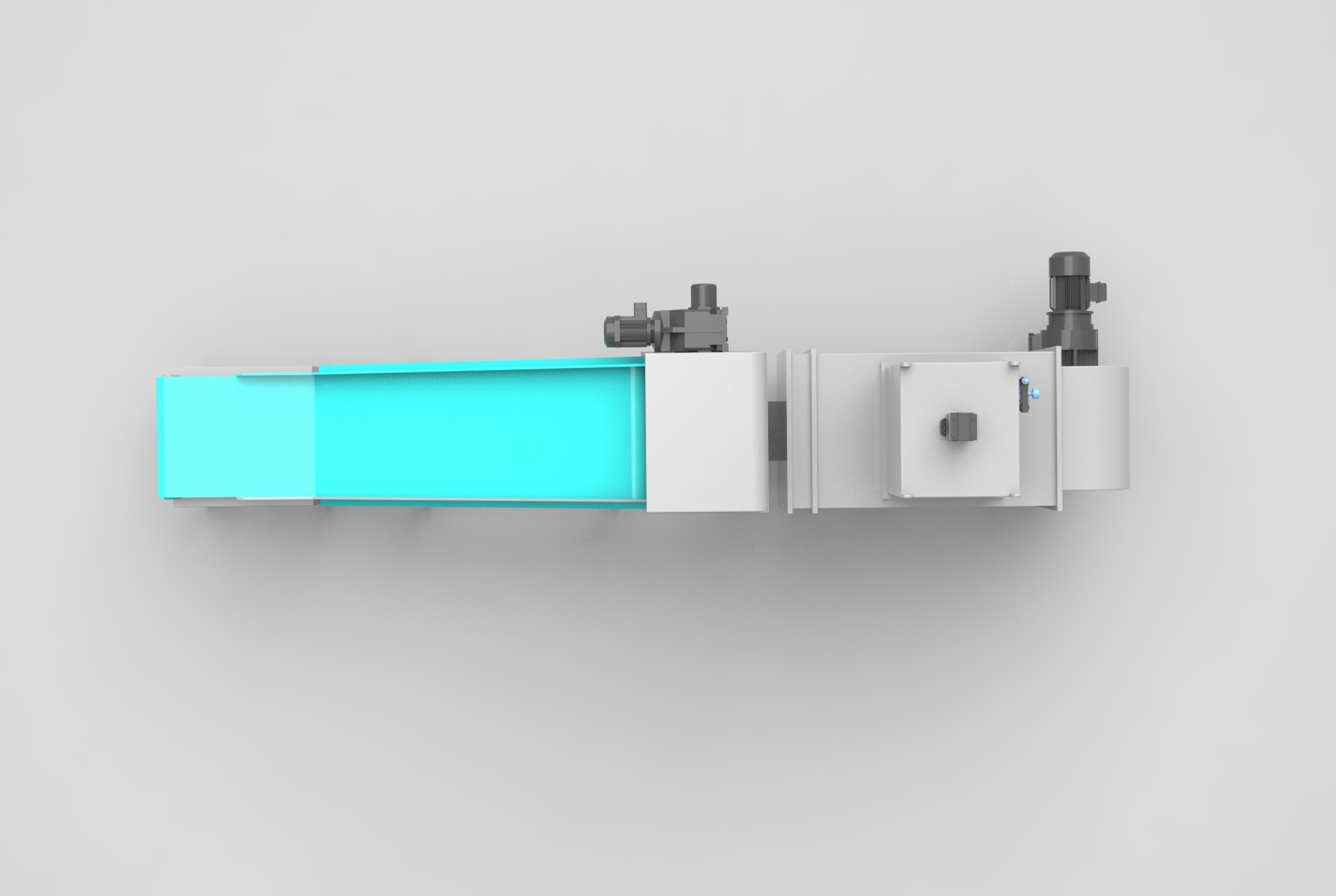

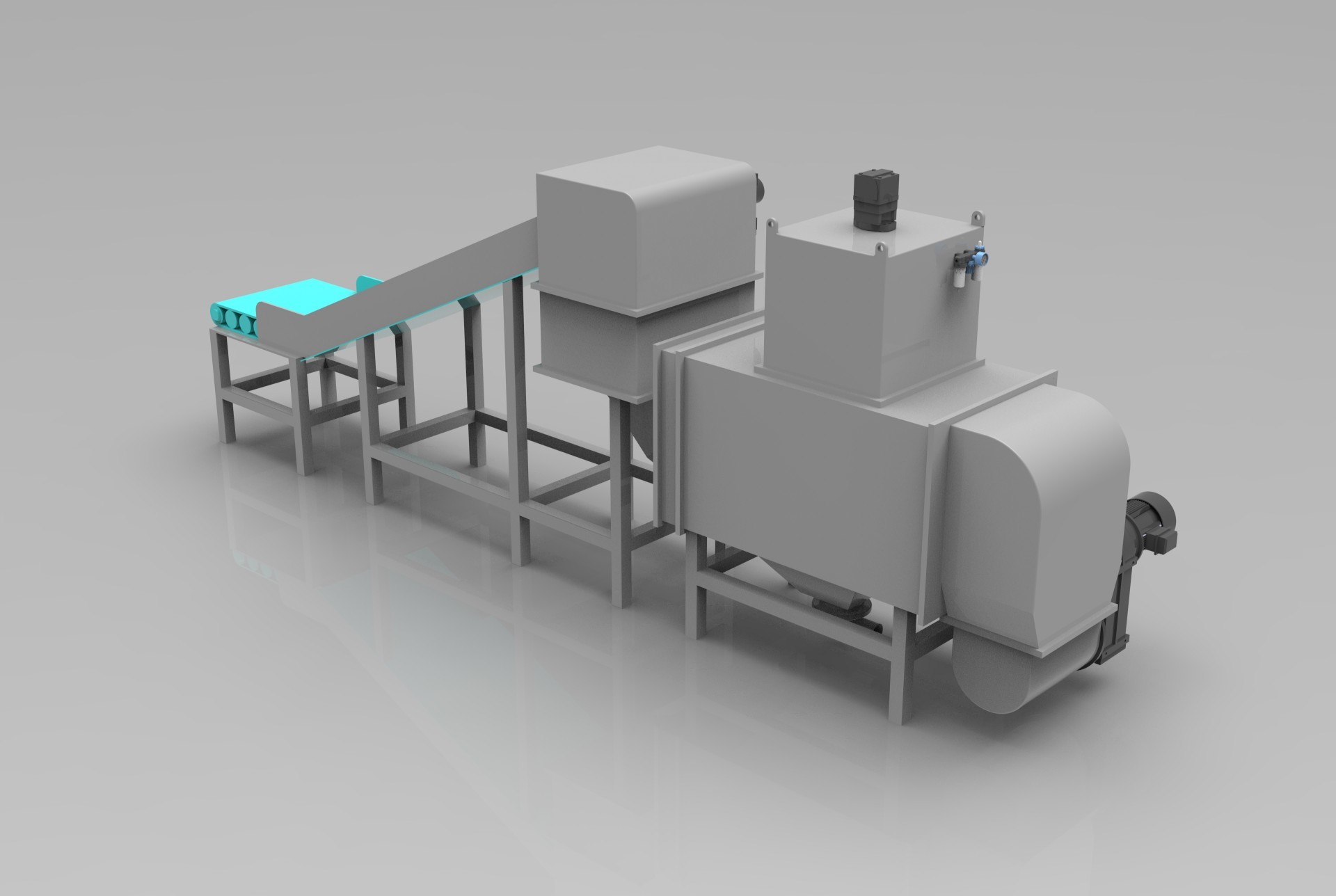

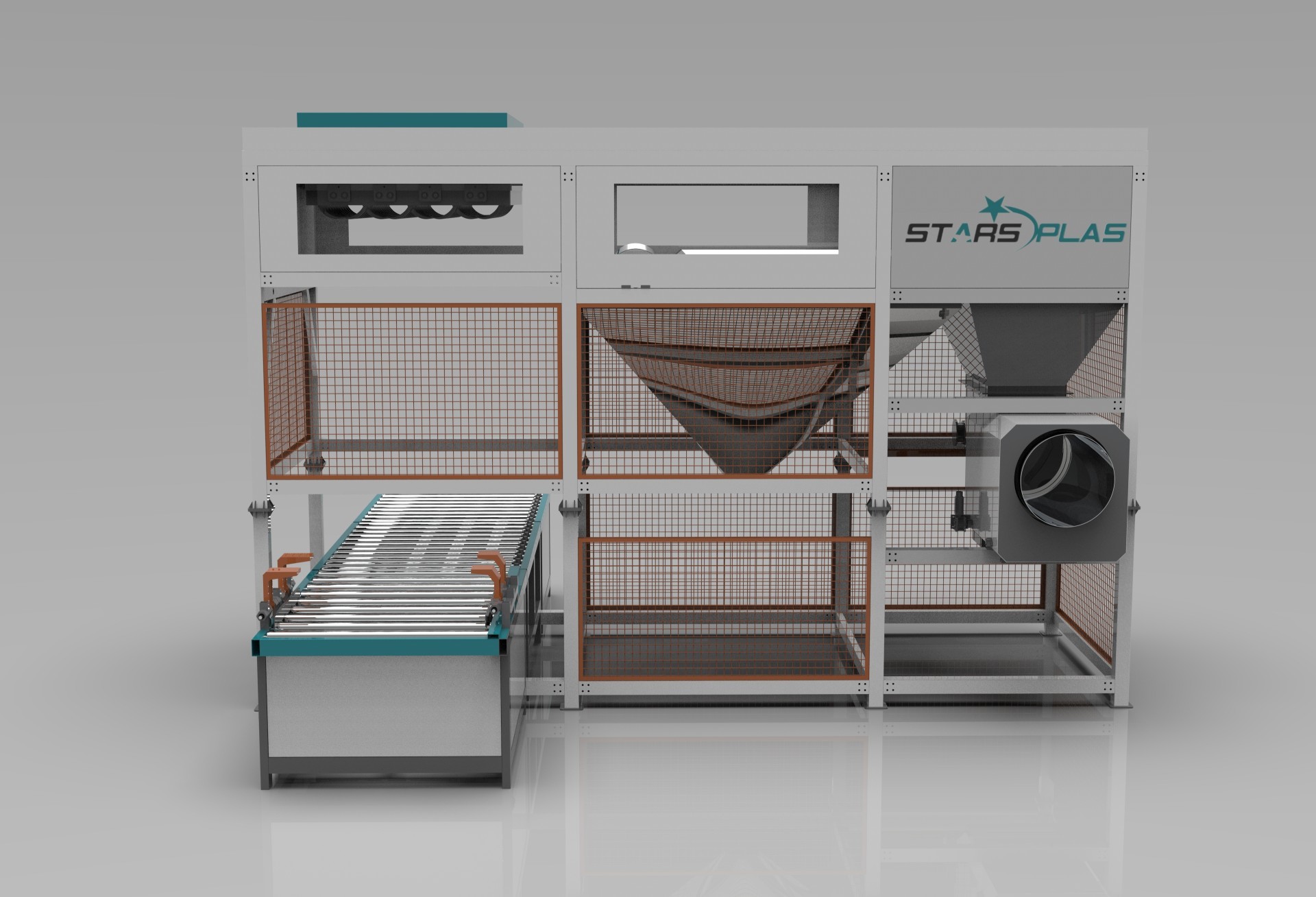

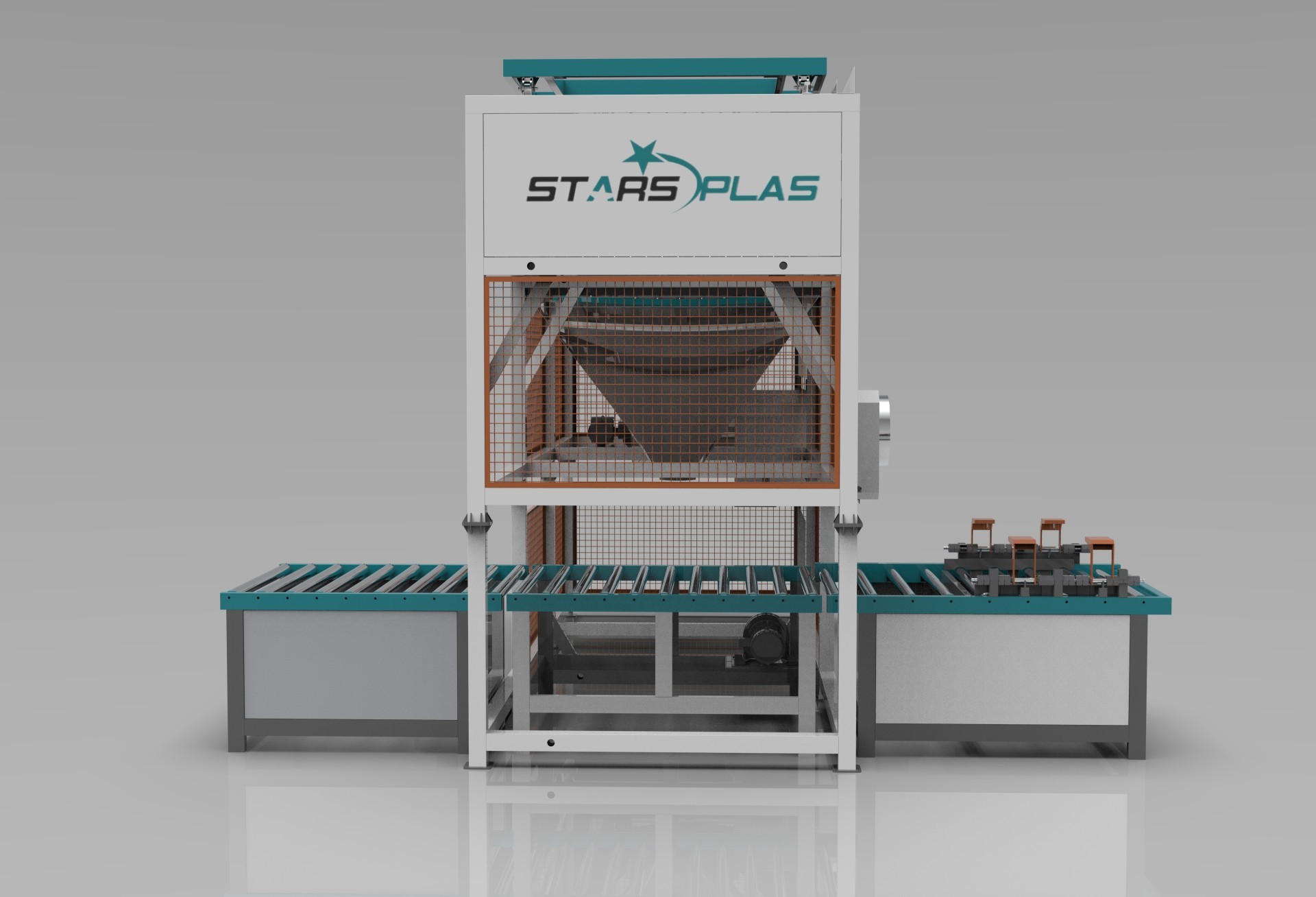

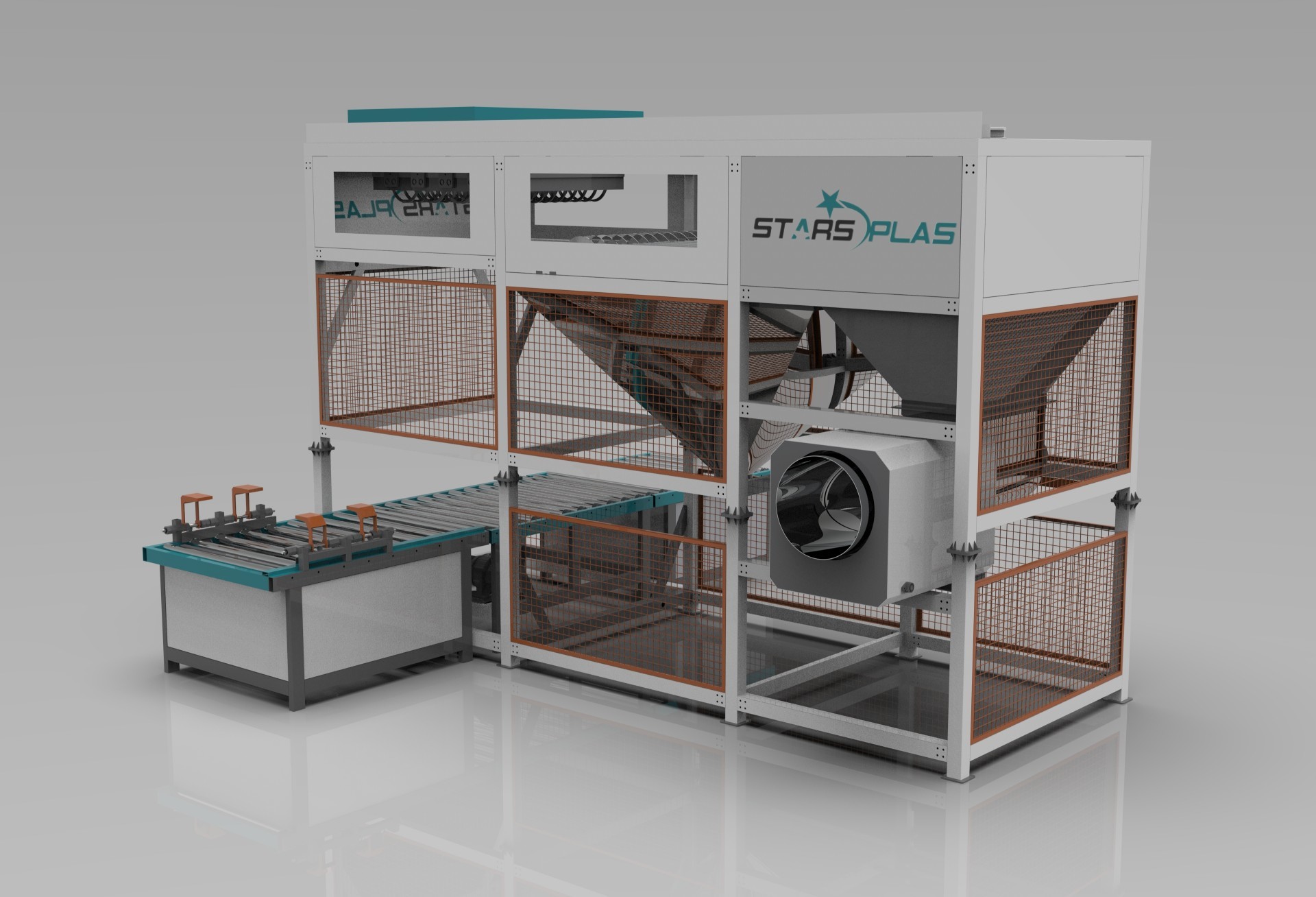

Layer-by-layer automatic unpacking machine

Workflow:

The layer-by-layer automatic unpacking machine uses a roller conveyor to automatically transport the entire pallet of stacked bags to the unpacking machine's bag grabbing area. The grabbing mechanism of the unpacking machine descends to grab a whole layer of bags, then lifts and horizontally moves the entire layer of bags. The cutting device breaks the bags, and the material emptying device clears the material from the bags, allowing the material to fall by gravity into the discharge hopper, while the empty bags enter the waste bag collector and are output after being compressed.

Once the entire stack of bags is unpacked, the roller conveyor will automatically transport the empty pallet to the pallet collection mechanism, completing automatic collection and stacking.

Technical Features:

1) High integration: The equipment integrates functions of automatic feeding, automatic unpacking, automatic pallet collection, and waste bag collection.

2) Intelligent control: Built-in PLC program, adjustable unpacking speed, automatic fault alarm.

3) High empty rate: Approximately 99.9% high empty rate, with very little material residue in the empty bags.

4) Automatic waste bag collection: Empty bags are automatically collected and compressed for output by the waste bag collector.

5) Automatic collection of empty pallets: Empty pallets are automatically collected and stacked by the pallet collector.

6) Less bag debris: Compared to similar equipment, there is less bag debris.

|

|

|

|

|

|

|

|