Global Solutions

WMS System

1. Overview

WMS is a system platform that implements warehouse logistics automation information management. It is mainly composed of core systems such as intelligent warehousing management system (WMS) and intelligent warehousing interface system (INTS). It is the core of the entire logistics management control system, and its purpose is to achieve The information management of automated three-dimensional warehouses enables real-time traceability tracking and management of materials, cargo locations, and automated three-dimensional warehouse equipment in the warehouse, and completes material management, inventory management, and cargo location management in a timely manner through the WMS system. The WMS control system independently developed by Zhejiang Zhongyang Liku Technology Co., Ltd. is connected to ERP/MES and other management systems, and connected to WCS to realize multi-level and multi-dimensional management of materials, and realize the integrated management of multi-mode production, storage and distribution of materials.

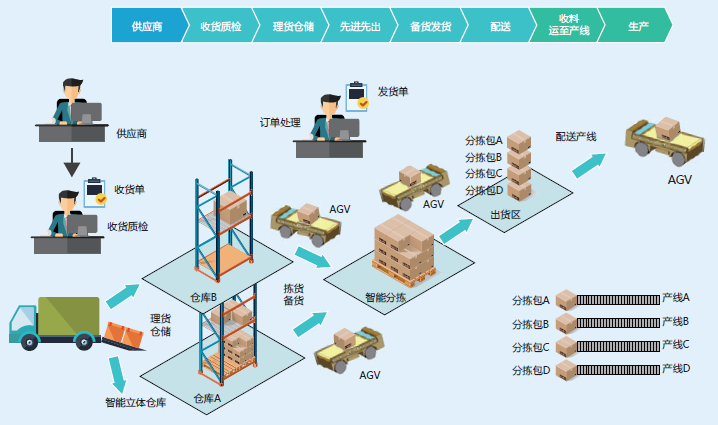

2. Schematic diagram

3. Basic

data of main functions: It is the basic data for maintaining the WMS system. It mainly includes basic data information such as materials, warehouse areas, and cargo locations. These data information can be synchronized with upper-layer information through interfaces, or can be defined in the WMS system.

Warehousing management: Complete the entire process from receiving goods to putting on shelves. Complete the warehousing order management, receipt grouping, and shelf confirmation modules of the automated logistics system. Supports many different methods of warehousing operations.

Outbound management: Realize the entire process from document creation/synchronization to ERP, outbound, and shipping. Complete the order allocation, wave processing, outbound picking, and shipping modules of the automated logistics system, and support multiple methods of outbound operations.

Inventory management: Realize the management of products in stock. Including inventory inquiry, replenishment, movement, inventory freezing, adjustment and other functions in the warehouse.

System management: realizes the function of system permission management, mainly including the definition and management of permissions, roles, and users.

Task management: Realize task query and management operations for incoming and outgoing operations within the system, mainly for the management and scheduling of operating tasks in the logistics center.

Report statistics management: Realize the report query and statistical functions of the main business. It mainly includes inbound and outbound reports, inventory reports, inventory reports, empty storage reports, and validity reports.

Log management: Realize the recording and traceability management of logs in the operation process.

Return management: Realize the entire process from material return and after-sales to completion on shelves. It mainly includes return warehousing, quality inspection returns, returns out of warehousing, exception handling, etc.

Early warning management: Realize early warning notification functions such as the status and quantity of materials in storage. It mainly includes safety stock early warning and expired material early warning.

4. Main advantages

1. Clear inventory management.

The calculation and recording functions of WMS can easily realize quantity statistics. Warehouse managers only need to register the goods during the daily purchase process, and register the goods during the shipment and sales process. The software can automatically record and calculate the changes in the quantity of goods types and models in the warehouse. With just one click on the computer, the statistical data can be seen instantly.

2. Refinement of warehouse management

. After the entire warehousing operation process is controlled through WMS, very refined constraints and guidance are provided for employees' operational requirements and link connection. Generally, after changing from the traditional management model to WMS management, the operating efficiency of the warehouse will increase by at least 30%.

3. WMS can standardize full-process operations such as entry and exit, inventory, etc.

The warehouse can be managed and controlled through the WMS warehouse management system, enabling enterprises to control flow operations, and standardizing full-process operations such as warehouse entry, exit, inventory, and returns.

4. Understand the inventory status in real time and improve the accuracy of decision-making.

By effectively recording information and connecting it with other operational function data in real time, the WMS system can accurately reflect the inventory situation and provide a strong basis for decision-making for corporate decision-makers.

5. Automatically carry out report statistics to save manpower and material resources.

Warehouse personnel can set various reports through various types of the system. The system will automatically summarize the required data and automatically produce various reports for enterprise personnel to view in a timely manner.

6. Optimize the warehousing and logistics process

through data collection and control solutions to warehousing and logistics production to improve output.

7. Traceability of production, warehousing, and logistics

through powerful barcode/RFID automatic identification technology with WMS to ensure that each product is traceable. , every product can be traced.

8. Improve order processing efficiency.

Orders are synchronized to the WMS system. Warehouse personnel can use handheld terminals to download orders and ship them at the same time, improving order processing efficiency.