Global Solutions

Mute Pad Laminating Machine

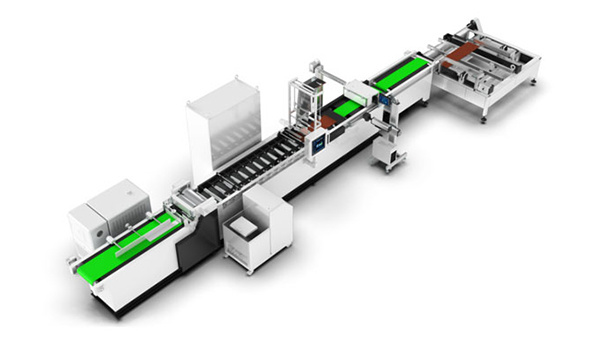

The floor pad laminating machine equipped with the automatic cutting system and lateral trimming system is specially used for laminating the cushion pad (IXPE/EVA) to the back of the floor. Starsplas mainly produces floor mat compound machine 310 and floor mat compound machine 200. Floor mat compound machine 310 is specially designed according to the requirement of users in the floor industry. Floor mat compound machine 200 featuring steady operation and convenient adjustment has been highly praised by users. Both the fully-automatic type and the semi-automatic type are available. HF 310 is applicable to back laminating of compound floors, wood floors and SPC floors.

Product advantages

1. Bond the prime material on the back of the floor to improve the sound insulation capability.

2. After adjusting the floor leveling system, the floor will be glued together with the conveyor belt, the cushion will be pressed tightly by a rubber roll, and then trimming will be performed.

3.It significantly improves the working efficiency, saves the labor cost and reduces the waste of cushion pads (IXPE/EVA).

Technical specifications

|

Coating width |

80~310mm |

||||||||

|

Lamination length |

600~1850mm |

||||||||

|

speed |

60-70m/min |

||||||||

|

thickness |

3~20mm |

||||||||

|

Total power |

35kw |

||||||||

|

Gross weight |

3900kg |

||||||||

|

Overall dimension |

12745*2300*2000mm |

||||||||

Standard configuration

|

Production structure |

|||||||||

|

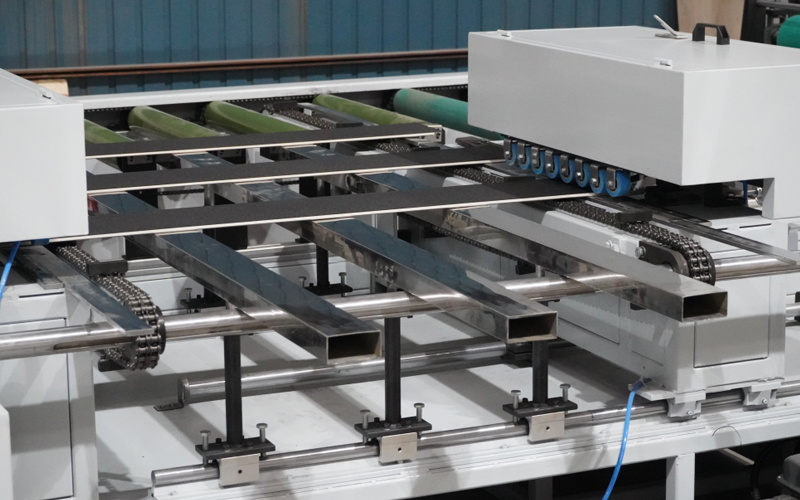

In feed conveyor |

This system is equipped with specially designed belt, passing the floors one by one. |

||||||||

|

Motor and conveyor system |

This system are equipped with frequency-converter and Cycloidal pin gear speed reducer. This machine is motored by transmission shaft , conveyor roller and guide roller.All the laminated rollers are made of NBR (nitrile rubber buna) ,it is endurable. The |

||||||||

|

Unwinder for IXPE(EVA) rolls system with servo motors |

This system is designed for making the floors pass through the machine in the same position. We can control the straightness of the flooring line with floors which are with different width, this system guarantees the straightness of the compacting of soft film and floors. |

||||||||

|

Hot melt glue(PUR/PSA) spreader and drying system |

The glue spreader system is consist with ANILOX roller and glue blade. The drying system is consist with heating oven, far infrared heating light and draught fans. The soft film goes through the the drying system after coating the glue in order to volatilize the solvent. The temperature of the drying system can be adjusted by the temperature controller till meeting the right temperature. |

||||||||

|

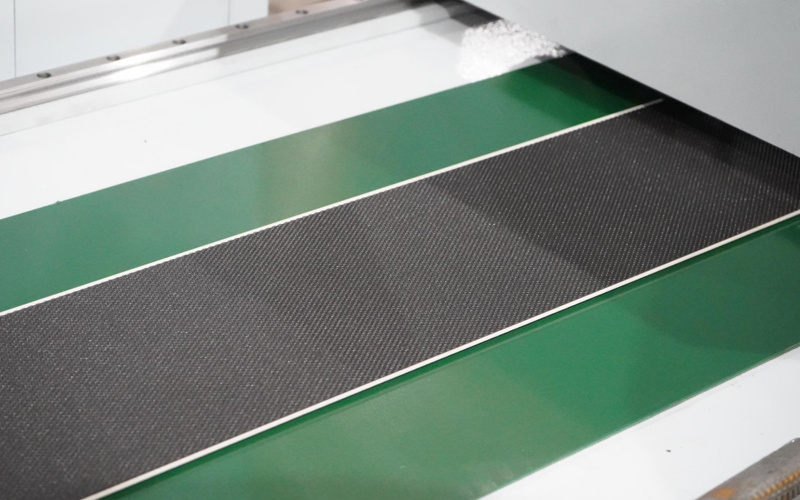

The laminating system |

The laminating system is consist with four support rollers and laminating rollers. The gap of the support rollers and laminating rollers can be adjusted easily according to the thickness of the flooring and soft film. |

||||||||

|

The cutting and trimming system |

After the flooring is laminated with the soft pad, the auto cutting machine is programmed to cut off the soft pad by PLC system, after that ,the flooring will transfer to the edge shaving side for trimming the extra soft pad one by one. |

||||||||

|

Electronic system |

All the electronic parts are designed reasonable, and adjusting easily. |

||||||||

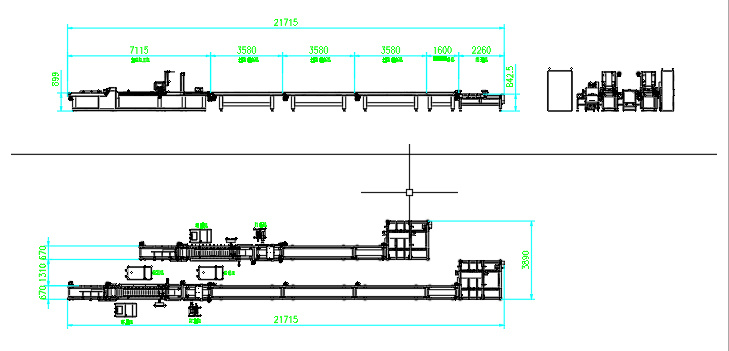

Three views of the product

Q&A

1. What kind of material do we mainly use for mute pads?

Starsplas mainly uses IXPE and EVA material mute pads, among which more IXPE material mute pads are used, and can also be configured according to customer requirements.

2. Why do floors need IXPE mute mats?

The Noise Pads of Starsplas are made of outstanding IXPE, a new development in foam technology. IXPE is a closed cell foam that is 100% waterproof, mold, mildew, rot and bacteria resistant. Without this layer of noise-quieting underlayment, the floor's laminate can quickly become wet, warp, and mold, compromising its overall integrity. And over time, moisture can also break down the floor adhesive, causing the floor to start warping. Secondly, the mute pad can insulate sound, and compared with cork pad, IXPE provides better sound insulation effect. 1.5mm IXPE has an IIC rating of 59-60, while 1.5mm cork pads are 53-55.

Product picture