Global Solutions

Grooving Machine Solutions

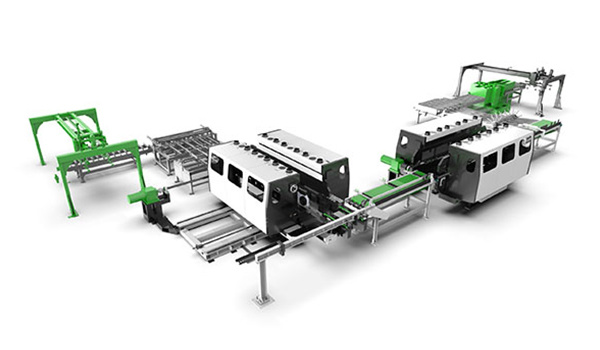

The grooving machine is mainly used for grooving panels. The long edges are grooved first, followed by short edges. Starspla produces both ordinary grooving machines and high-configuration grooving machines. Ordinary grooving machines include model 6+6 and model 8+8. High-configuration grooving machines are chevron floor grooving machines.

Product advantages

We adopt the grooving technology of YASUDA, a famous Japanese company in the floor industry.

1. This machine composed of a T-shaped chain, a ceramic guide and three V-shaped guide meshing mechanisms almost generates no wear or deformation and guarantees the stability of high-speed machining.

2. The one-piece pressurizing device guarantees uniform and stable pressure.

3. The chain is equipped with a blowdown process groove and an air dust collector, which effectively prevents dust retention on the chain and guarantees a high machining precision.

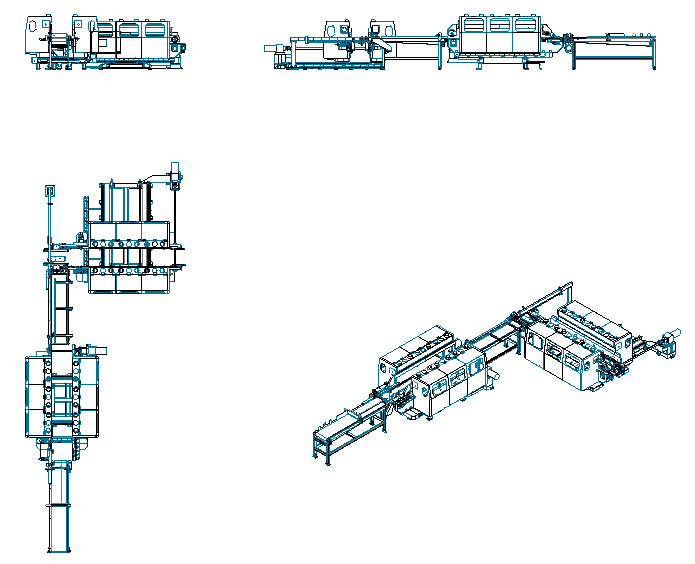

Process flow

Section A: forklift ˃ automatic hydraulic lifting platform ˃ vacuum suction cup system ˃ inclined roll table

Section B: longitudinal multi-blade saw ˃ acceleration roll table ˃ Lifting belt roll table ˃ climbing roll table ˃ flip board slideway

Section C: longitudinal conveying belt conveyor ˃ longitudinal milling ˃ transition belt conveyor ˃ horizontal double-end milling

Section D: flip board conveyor ˃ artificial packaging

Technical specifications

|

Pallet specification |

Tray maximum: 1000mm; Large plate specifications: length 1250mm, width 950mm, thickness 4-15mm. |

||||||||||

|

Small board specification |

The width is 125-600mm, and the large board is cut into 10 smaller boards at most. |

||||||||||

|

Speed and capacity |

Main speed and frequency of the whole line: longitudinal milling 60-80m/min, about 60 pieces of standard board per minute (standard board 8.2*150*1220, single piece area 0.18 square meters). |

||||||||||

|

Range of finished floor sizes |

length:950、1220、1850mm |

||||||||||

Applications

It is mainly applied to automobile, aerospace, construction and other industries.

Three views of the product

Q&A

1.How does the Starsplas floor slotting machine make IF4 clips?

The SPC floor slotting machine is specially designed for SPC floor slotting. It first adopts manual positioning, and then enters the longitudinal multi-blade saw, and cuts into 5-8 pieces. The lifting belt conveyor passes through an accelerating roller table and then turns 90 degrees, then transfers to the longitudinal separation belt conveyor, and then opens the vertical and horizontal grooves.

2. What are the advantages of IF4 snap-on floor?

"Our one-piece drop-lock system is quickly becoming the industry standard because it offers a faster, more cost-effective way to sustainably manufacture drop-lock solutions and is so simple to install that anyone can Do it!" - As CEO John Rietveldt says, the Innovations4F snap-on system for floor tiles is almost a unique trend in the current market because of its outstanding ease of installation. Its 3L TRIPLELOCK AND CLICK4U is suitable for all flooring materials including the current popular SPC waterproof flooring - rigid vinyl planks.

3. What are the recommended tools and materials for installing IF4 snap-on floor?

Safety glasses, tape measure, square, utility knife, straight edge, spacers, chalk line, embossed leveler/floor patch (if necessary), rubber mallet.

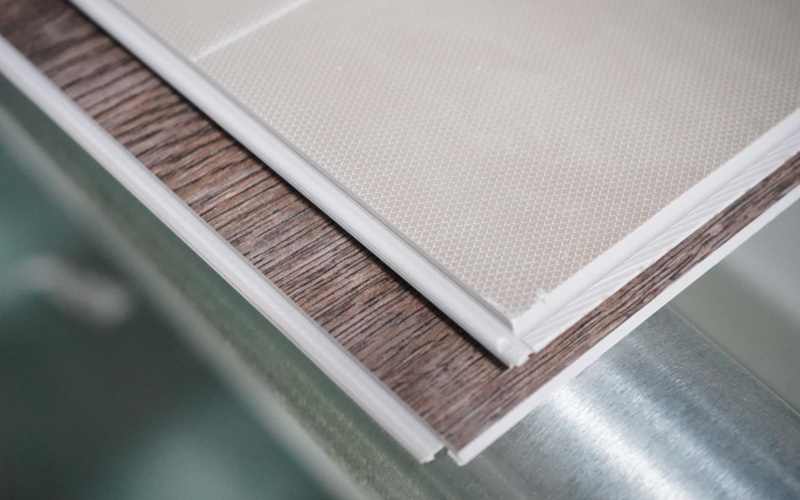

Product picture