Global Solutions

Fully-automatic Packaging System

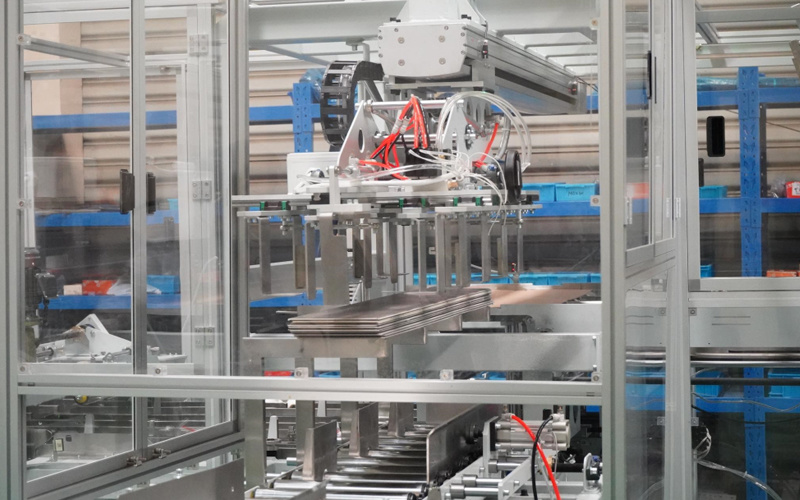

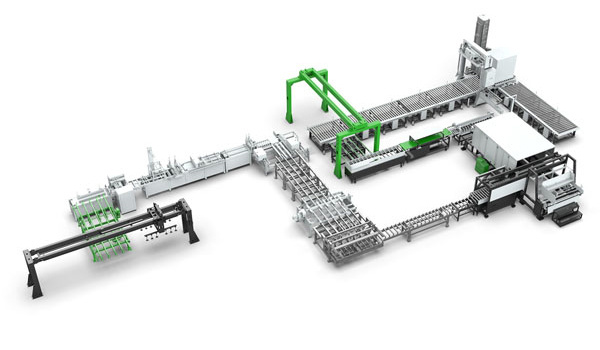

The fully automatic packaging system sold by Starsplas is used for automatic packaging of finished floors. The whole system can realize automatic conveying, packaging and stacking. 90% SPC, LVT and WPC floor manufacturing factories choose this machine, because it can save labor force and time cost.

Machining process

The whole system includes the automatic conveying, automatic packaging and automatic stacking. The handling process is:

1. Move floors from the back film laminating machine into the belt conveyor for conveying;

2. The belt conveyor conveys floors after dust removal into the feeding area;

3. Collect 5 or 6 floors as standby floors for feeding;

4. Feed cartons, move into the next workstation for gluing;

5. Inject the hot melt glue by using the peristaltic pump for 3 sides of gluing;

6. Convey into the stacking area after gluing;

7. The mechanical arm collaborates with the photoelectric sensor to complete stacking onto the tray.

Technical specifications

|

The packing capacity |

400~480 cases/hour, 3200~3800 cases/day |

||||||

|

Applicable size |

Length: 1850mm, width: 320mm, packing height: 30~80mm |

||||||

|

Sealing method |

Hot melt adhesive |

||||||

|

Compressed air |

The consumption of 5kg/cm2 is 300L/min |

||||||

|

Carton storage |

200 (Thickness 3mm) |

||||||

|

Size conversion required time |

Automatic size adjustment, complete in 5 minutes |

||||||

|

Protective measure |

The main body will fully cover the safety guardrail |

||||||

|

Worker demand |

1 person to drive the forklift, monitor the operation of the machine, load cartons (200 pieces per carton, 18~20 minutes) |

||||||

Applications

The fully-automatic packaging system can be used for packaging of various regular or irregular materials, such as powder, liquids, particles, and blocks, and can also adapt to different types of packaging bags, such as standing bags, special-shaped bags, zipper bags, spout bags, etc. Therefore, it is very popular in the rapidly developing food, chemical, and manufacturing industries, and its significance is also incomparable. 。

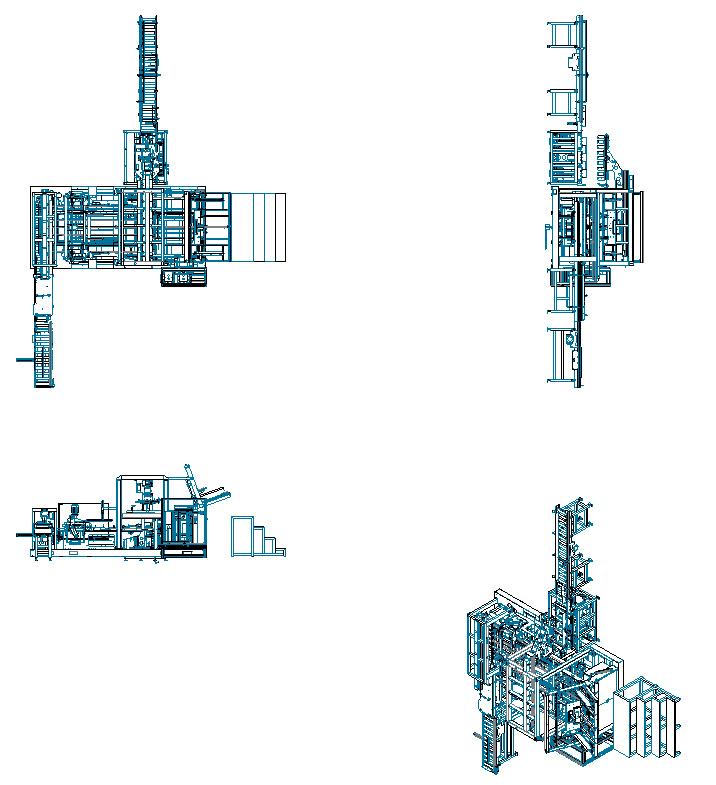

Three views of the product

Q&A

1. What is the difference between manual packing and machine packing?

① Packing capacity: 400-480 boxes/hour; such as 8 hours packing time: 3200 ~ 3800 boxes/day;

②Labor cost: workers 0.45 yuan/box, if machines are used instead of workers, workers can save 1440 yuan per day;

Worker requirements: 7 workers per shift are reduced to 1 or 2 workers, one worker drives the forklift and monitors the operation of the machine;

Another worker needs to add cartons (200 per box, 18-20 minutes, the price of the carton depends on the thickness, number of layers and printing, the range is 0.4-0.7 US dollars/piece) and rubber particles (hot melt adhesive, 20kg, 4 hours use, 2.8 US dollars/bag, 4g per 1.3 meters of glue line 3 sides).

Product picture