Global Solutions

Mixer Solutions

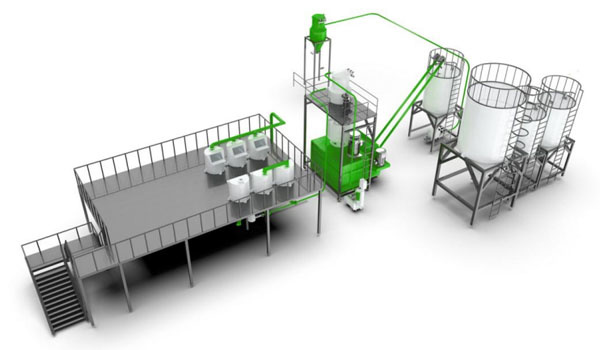

Starsplas automatic mixing system is specially designed for mixing workshops in the PVC industry or the WPC industry. This closed system is used for automatic metering, feeding, mixing and feeding of kinds of powders, particles, and liquids for extrusion. This system saves labor force and prevent employees from directly contacting powder.

Product advantages

1. Automatic feeding system - unattended operation

SPC PVC automatic mixing solution is specially designed for mixing workshops in the PVC industry or WPC industry. The closed system is used for automatic metering, feeding, mixing and feeding of kinds of powders, particles, and liquids for extrusion. It saves labor force and prevent direct contact with powder. 。

2.Central dust collection system - dust free

Mixing workshops in the PVC industry and WPC industry are characterized by much dust and high mobility. When using the centralized feeding system, we choose to connect the dust collector and the dust production opening for recycling. Dust-free workshops are not only designed to meet the modern industry standard, but also save a lot of materials and labor force.

3.Central control system——intelligence

The intelligent control system is designed to avoid errors and losses arising from artificial operation, such as non-conforming products in batches and secondary processing waste caused by the wrong incoming material formula. The lack of automatic feeding will cause insufficient filling, which will bring damage to the screw and extrusion machine. The key problem is the lack of an automatic production-based material calculation system.

Technical specifications

| component | power | ||||||

| Heating/cooling mixer combination | 245KW | ||||||

| PVC&CACO3 automatic dosing weighing system | 18.5KW | ||||||

| Automatic additive weighing system | 7.8KW | ||||||

| Additive dust removal system | 1.5KW | ||||||

Applications

It is widely applied to chemical, battery raw materials, coatings, dyes, pesticides, pharmaceuticals, food, feed, additives, new refractory materials, electronics, plastic, ceramic, fertilizers, metallurgy, mines, dry powder mortar, EPS and special building materials, such as powder and solid powder-liquid mixtures.

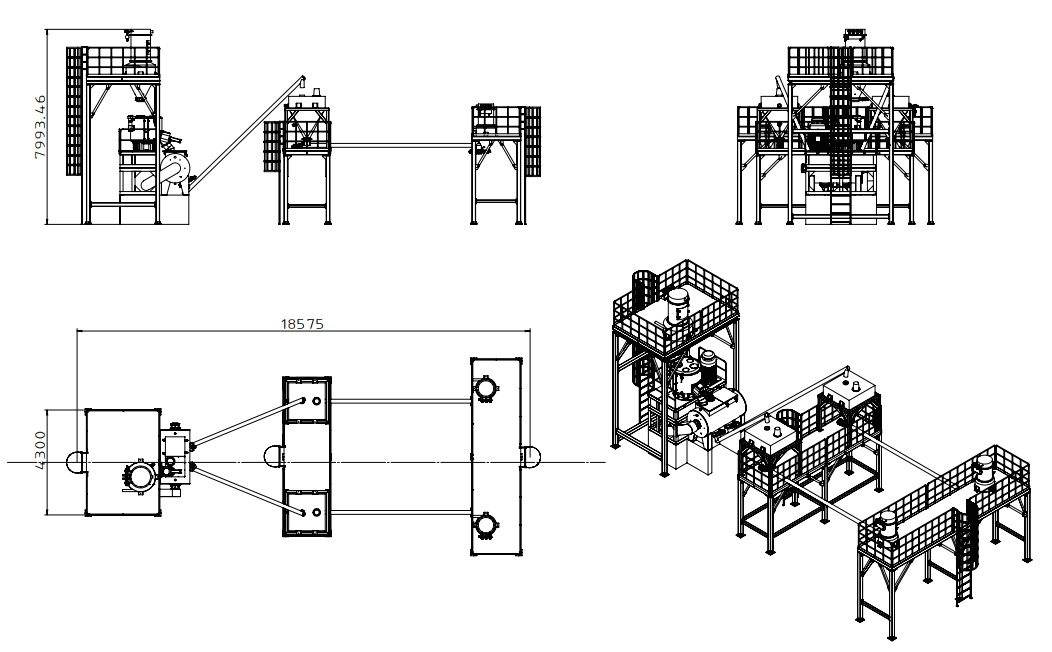

Three views of the product

Q&A

1. How to maintain the mixer?

① Be sure to follow the operating procedures of the equipment, which is the best maintenance for the equipment.

②. Note that after the equipment is started normally, then feed and mix. The feed should be added slowly according to the required order.

③. Prepare sealing rings, rubber rings for couplings, V-belts and rolling bearings. The working parts of these parts are prone to failure, and should be replaced in time if necessary. The tightness of the V-belt installation, all parts of the equipment should be cleaned, decontaminated and dust-removed.

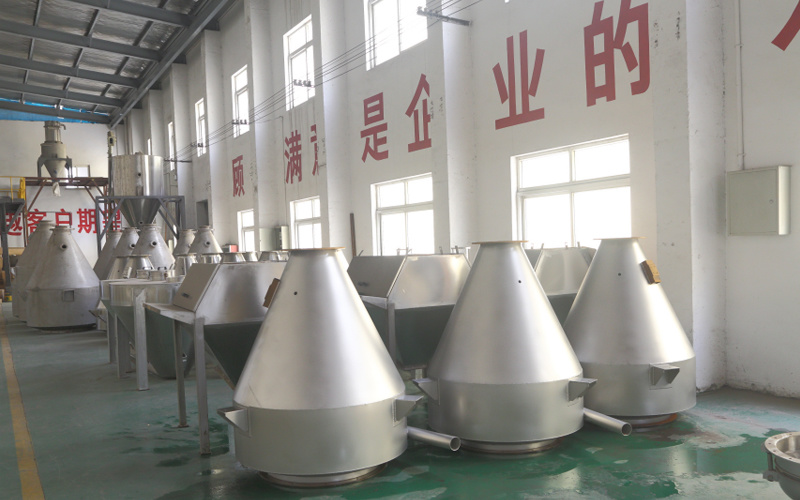

Product picture