Global Solutions

Solutions

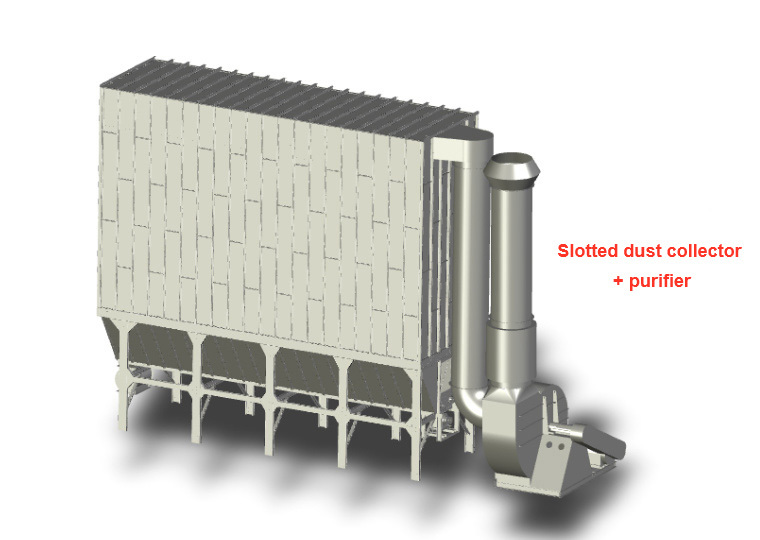

Dust Collection System

The dust extraction systems sold by Starsplas are designed to collect the dust generated by sawing and profiling of flooring production lines. The dust collection system is mainly composed of the upper box, ash hopper, ash conveying system and control system. Dust flows into the ash hopper and then into the box via the air inlet. Some large dust particles directly fall into the ash hopper under the action of inertia collision and natural settling. Other dust particles rise along with the airflow into the bag.

Product advantages

1. This system adopts standard design, sound quality control processing and modular assembly.

2. Low-pressure blowing technology: the electromagnetic pulse valve featuring low pressure, high efficiency and long service life is applied, and the blowpipe is designed and processed in special means, which fundamentally changes the cleaning method of bag-type dust collectors.

3. Application of detection and monitoring technology: according to the features of the dust collector, advanced online dust collector working pressure detection unit and material level detection unit are provided to detect faults during working of the system.

4. The application of the PLC guarantees automatic operation of the dust collector in the workshop.

Technical specifications

|

Serial number |

Item |

Model |

Technical parameters |

|||||

|

1 |

CNC pulse bag filter |

SMZ-6A-285-4000 |

①Q=55860m3/h |

|||||

|

②Filter area=465.5m2 |

||||||||

|

③Electrostatic filter bag, taper |

||||||||

|

④Spring: pressure spring |

||||||||

|

2 |

Twin-screw conveyor |

GBS-700 |

①5650x700 |

|||||

|

②Power:3KW |

||||||||

|

3 |

Unloader |

RV-5 |

①Power:1.5KW |

|||||

|

②Self - check function, positive and negative rotation |

||||||||

|

4 |

Draught fan |

MQS5-54№10C |

①Q=45000m3/h~58000m3/ h |

|||||

|

②P=2500Pa |

||||||||

|

③N=75KW |

||||||||

|

④With the overall steel machine frame and shock absorbers |

||||||||

|

5 |

Main pipe |

φ=820~φ250 |

①Material: Galvanized coil |

|||||

|

②Length: ≤40m |

||||||||

|

6 |

Pipe hanger |

/ |

Material: Angle steel flat steel, wire rope |

|||||

|

7 |

Electric control cabinet |

/ |

①Automatic frequency conversion control |

|||||

|

②Inverter: Taida |

||||||||

|

③Control: PLC |

||||||||

|

④Interlock Control |

||||||||

|

⑤75kw×2,2.2kw×2 |

||||||||

|

8 |

Pneumatic valve |

φ=560~φ=360 |

/ |

|||||

|

9 |

Dust precipitator fire spray |

/ |

Manual |

|||||

|

10 |

Explosion - proof automatic pressure relief door |

/ |

When the duster is under positive pressure, the door opens automatically. |

|||||

|

11 |

Temperature detection and alarm system |

/ |

Control by PLC |

|||||

|

12 |

Dust catcher anti-bypass system |

/ |

Control by PLC |

|||||

Applications

1. Metal processing industry

Some nonferrous metals will produce toxic dust during production and smelting, such as beryllium dust that will cause lung granuloma; silicon-containing dust that will cause pneumoconiosis; arsenic dust that will induce lung cancer. In the meanwhile, dust that fall onto the rotating components of the machine will accelerate wear of components and reduce the working precision and service life of the machine.

2. Port handling industry

During handling and transportation of bulk materials at the port, a lot of dust will be generated, and there will be some other problems such as scattered materials and flying dust in the storage yard. Under the synthetic effect, serious dust pollution will be generated, and failure to handle it timely will cause safety hazards.

3. Iron and steel industry

During production, smoke, dust, powder and other pollutants will be very likely generated during production in factories. Such substances are unfavorable for environment treatment in the workshop, bring safety hazards and also do harm to the health of workshop workers. The dust collection system uses a dust collection pipeline network to connect the interface of the dust collection valve installed onto the factory wall or ground to the working mainframe installed at the initial end of the pipeline. When the dust collection hose is inserted into any of the interfaces, the system will start working automatically. The materials (dust, industrial debris, etc.) sucked by the dust collection brush head will be adsorbed into the dust collection bucket of the main frame.

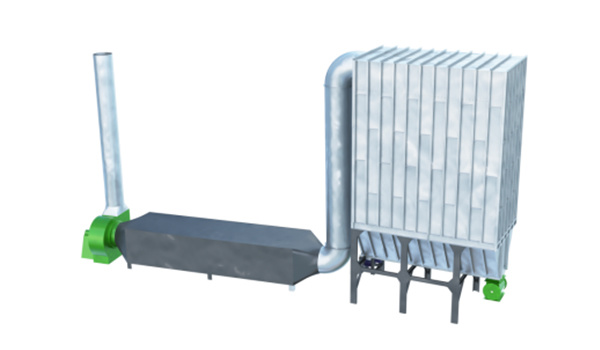

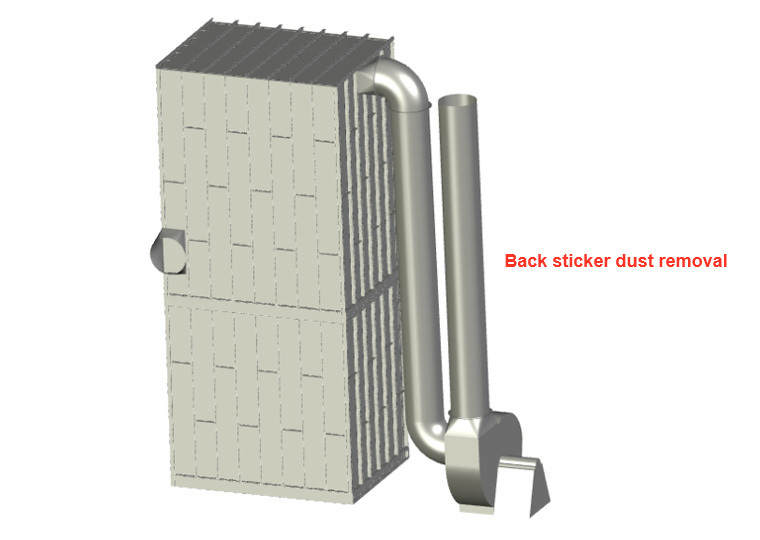

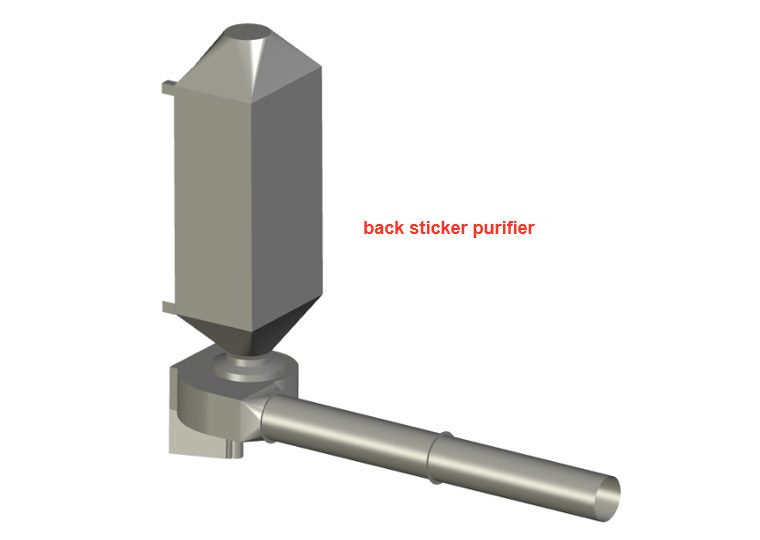

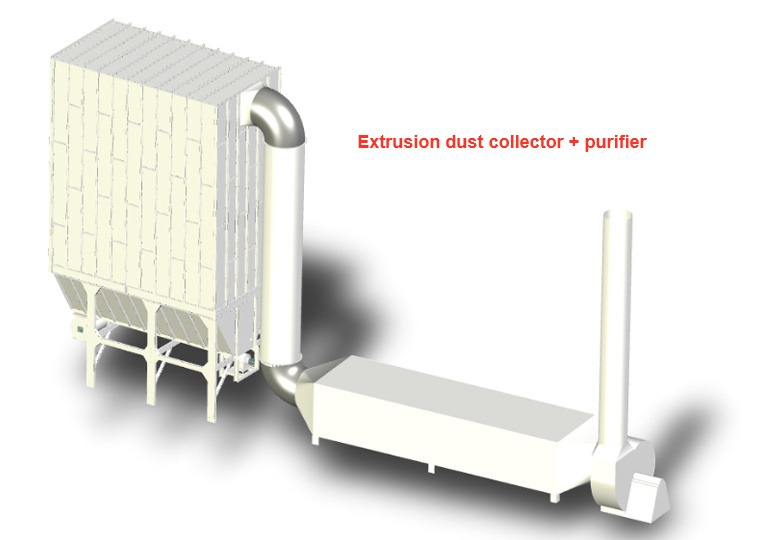

Product 3d Image

Q&A

1. What is the principle of injection system?

The dust removal system produced by Starsplas is a central dust removal equipment that is specially designed for centralized adsorption, treatment and recovery of wood dust generated by all woodworking machinery in the woodworking machinery processing workshops of furniture factories, floor factories, and wooden door factories. Process flow of dust removal equipment: One end of the main pipe is connected to the other end of the main box to enter the workshop, and it is laid according to the location of the factory equipment, and each piece of equipment is connected to the dust removal port of the production equipment through a (PVC) hose. The dust removal equipment uses a negative pressure fan as the adsorption power, and a pulse bag filter as the separation system, which is automatically controlled by the PLC central system. The frequency conversion controller is divided into manual frequency conversion and automatic frequency conversion. The dust generated in the workshop is attracted by the corresponding dust collection cover, air valve and branch pipe into the main air pipe and then enters the bag filter. The purified air is discharged up to the standard. The power used by the central dust removal equipment can be adjusted freely to achieve the purpose of energy saving.