Global Solutions

Solutions

Recycling System

Starsplas recycling system is mainly used for collecting panel materials/double-cut chips/other surplus materials generated during production of the whole production line to realize the purpose of cyclic utilization and save the cost of raw materials. The recycling system is mainly composed of the crusher, pulverizer, stocker, dust collector and induced draft fan.

Precautions

1. Safety: it keeps clean and prevents dust.

2. Maintenance: the blade should be replaced once 3-6 months. StarsPlas recommends that the blade should be replaced every 3 months. The safety line of the oil level should be checked monthly. Lubricating oil should be added when the oil level is lower than the safety line.

Technical specifications

|

length |

5000mm |

|||||||

|

Reduce motor power |

3kw (frequency control) |

|||||||

|

Transmission height |

2700mm |

|||||||

|

Conveying material |

PVC tape |

|||||||

|

Transport capacity |

1.8-3t/h |

|||||||

|

Linear velocity of conveyor belt |

15-20m/min (adjustable) |

|||||||

|

weight |

750kg |

|||||||

Applications

Starsplas recycling pulverizer integrates breaking, drying, pulverizing, grading and conveying. It can easily pulverize PVC, PE and PS materials, such as PVC pinch plates, pipes, rubber, leather, plant fiber as well as other plastic material and powder processing. It is also applicable to recycling of PVC pipes, boards, floors, profiles, aluminum plastic, PCB, resin and calcium carbonate-containing materials.

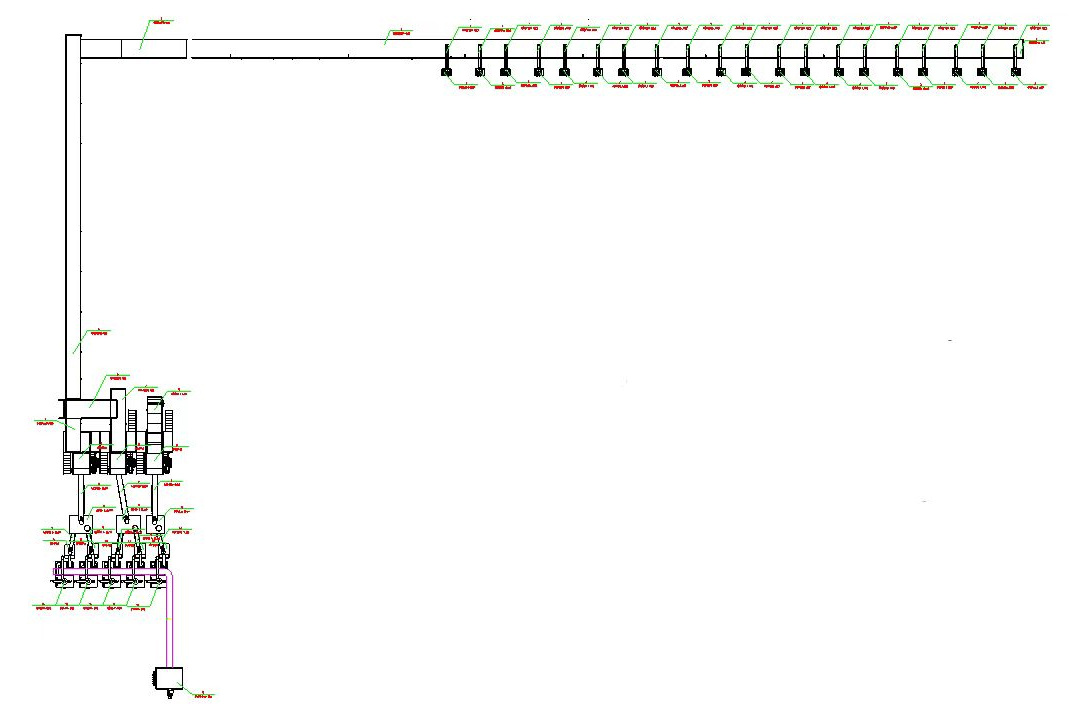

Three views of the product

Q&A

1. What is the capacity of this recycling machine?

The Starsplas recycling mill mainly includes two parts: a crusher and a milling machine. The power of the crusher is 75 kilowatts, and the capacity is 1.5-1.8 tons per hour; the power of the milling machine is 110 kilowatts, and the capacity is 1.2-1.5 tons per hour.

2. What are the advantages of the recycling machine sold by Starsplas?

① Standardized modular design is adopted, and the parts are interchangeable.

②The main knife is made of special alloy steel through a special special process, which has the characteristics of good wear resistance and high strength.

③The appearance is elegant and the structure is precise and compact. The electrical part adopts Delixi electrical components, which have functions such as automatic detection of overload protection. ④The machine is equipped with a safety switch and an emergency stop switch to ensure the safety of inspection and maintenance, which meets the ISO9001 certification standard and European safety standards.

⑤ The whole machine is equipped with a pulse removing device, which will not produce dust during the grinding process and is highly environmentally friendly.

Product picture