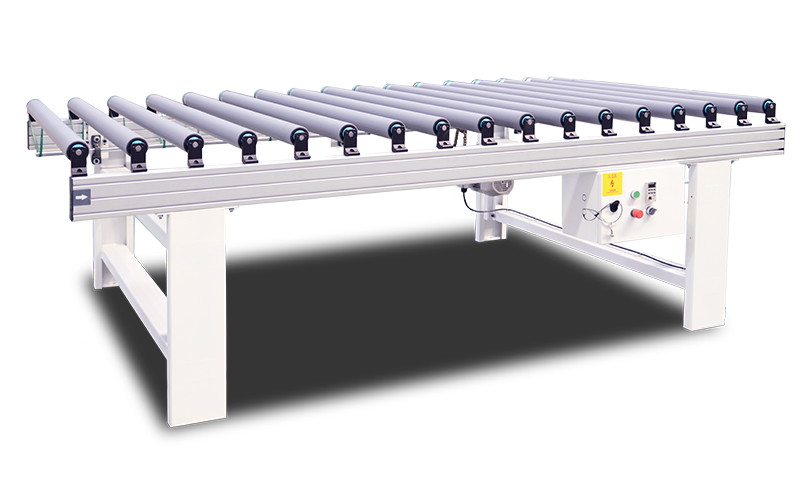

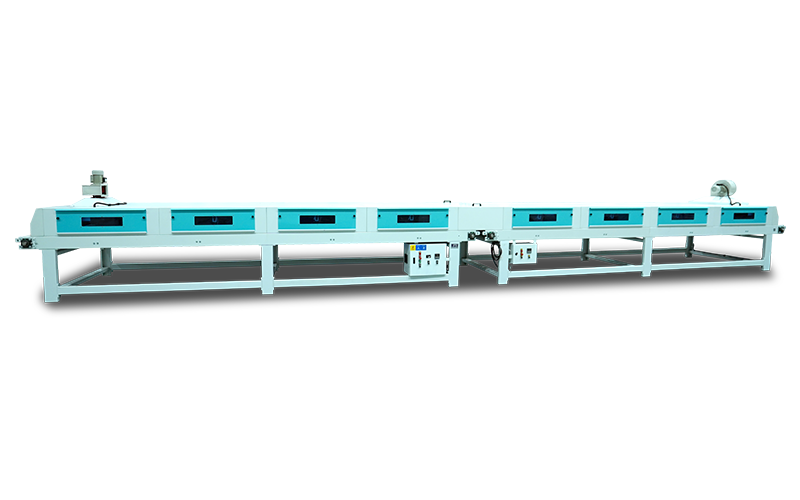

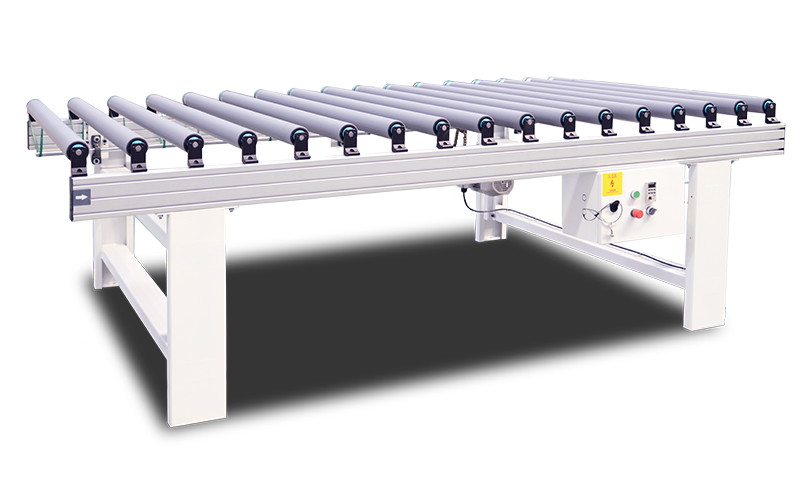

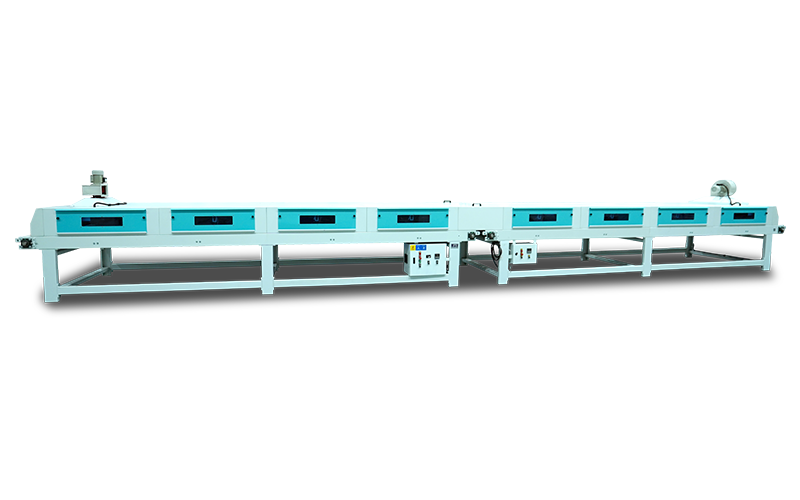

UV Production Line

80%

UV curing reduces drying time

5 times

Increases surface wear resistance

95%

uniform gloss level

66%

less energy

0

VOC emissions

less50%

repair needs

Product Parameters

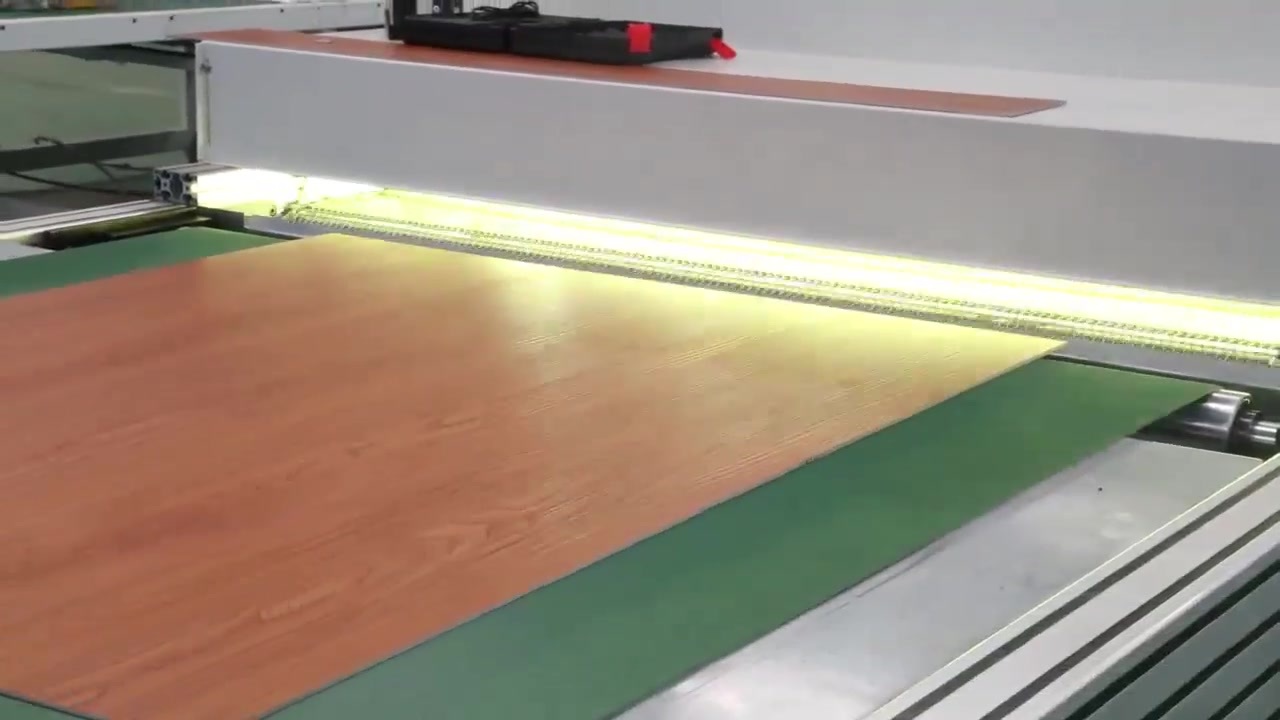

- Fast and Efficient Curing: Instant curing under UV light enhances production efficiency and reduces energy consumption.

- Uniform Coating Process: Advanced coating equipment ensures an even application of the UV coating, with no color variation or streaks.

- Multiple Gloss Level Options: Can be adjusted to provide glossy, matte, or ultra-matte effects according to market demands.

- Intelligent Automated Control: Equipped with an intelligent control system for automated production, improving stability and reducing labor costs.

- Environmentally Friendly: Uses eco-friendly UV coatings that meet international environmental standards, with no VOC emissions.

Our Advantages

The machine full modular design, special frame using full steel plate bending assembly (non-welding), the overall accuracy is high, while the tunnel part of the overall bending, Built-in reflective heat insulation film, good thermal insulation effect;

The whole machine adopts full PLC electronic control system, man-machine interface, which can monitor the coating situation in real time and facilitate operation.

Patent air circulation heat dissipation system, equipped with a 500w centrifugal fan for air pressure, and with an air filtration system, while a 1.1k w large flow centrifugal fan for ventilation.

The brush adopts a unique hanging fast disassembly structure, and with a cylinder fast locking, convenient for cleaning and replacement, with the high brush cleaning machine can achieve fast brush cleaning and replacement;

Technical Proposal

Applicable Scenarios

UV Production Line

StarsPlas is a modern equipment manufacturing company specializing in the research and development, design, manufacturing, sales and service of intelligent coating system equipment.

The company's main products include: flat coating series, line coating series, special-shaped panel coating series, etc., three series with more than 40 varieties, mainly covering surface coating methods such as roller coating, curtain coating, and spray coating.

After years of in-depth research in the field of coating equipment and combining cutting-edge technologies of well-known coatings at home and abroad, the company continues to design and develop every year, and has been rated as "National High-tech Enterprise", "Patent Demonstration Enterprise", "National Standardization Enterprise", "ISO9001 International Quality System", etc.

"Making better equipment and empowering every customer" is Tuogao's lifelong mission. We will always uphold the corporate values of "fairness, openness, synchronization, integrity, and innovation" to create greater value for you and your company.

The company's main products include: flat coating series, line coating series, special-shaped panel coating series, etc., three series with more than 40 varieties, mainly covering surface coating methods such as roller coating, curtain coating, and spray coating.

After years of in-depth research in the field of coating equipment and combining cutting-edge technologies of well-known coatings at home and abroad, the company continues to design and develop every year, and has been rated as "National High-tech Enterprise", "Patent Demonstration Enterprise", "National Standardization Enterprise", "ISO9001 International Quality System", etc.

"Making better equipment and empowering every customer" is Tuogao's lifelong mission. We will always uphold the corporate values of "fairness, openness, synchronization, integrity, and innovation" to create greater value for you and your company.

Global Solutions