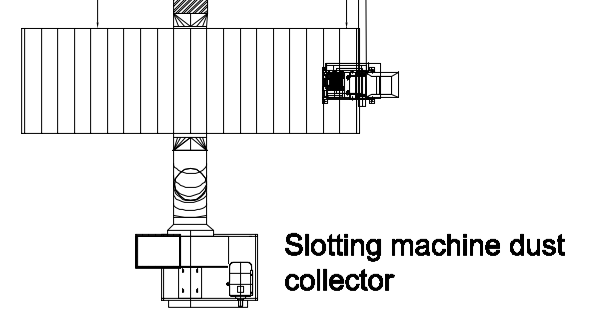

Dust Removal System

400-600(bag/hour)

Production Capacity

0%

Waste rate

15kw/380V

Machine Power

Electrical interlock

High safety

5.8X5X4(M)

Dimensions

100%

Automatic

Product Parameters

- Model Sd-396 modular dust collector

- Pulse solenoid valve

- Pulse control device

- Double row screw conveyor

- Double row screw conveyor supporting motor

- Automatic feeder

- Automatic feeder supporting motor

- Electrometer control system

- Model 4-73 No 12.5C Dust Suction Fan

- Blower motor

- Dedusting duct

- Vacuum pipe support, hanging, etc

- The main channel is equipped with electronic ash cleaning valve

- Silencer

Our Advantages

Advanced Technology

Rich Experience

Comprehensive After-Sales Service

Technical Proposal

Applicable Scenarios

Dust Removal System

Global Solutions